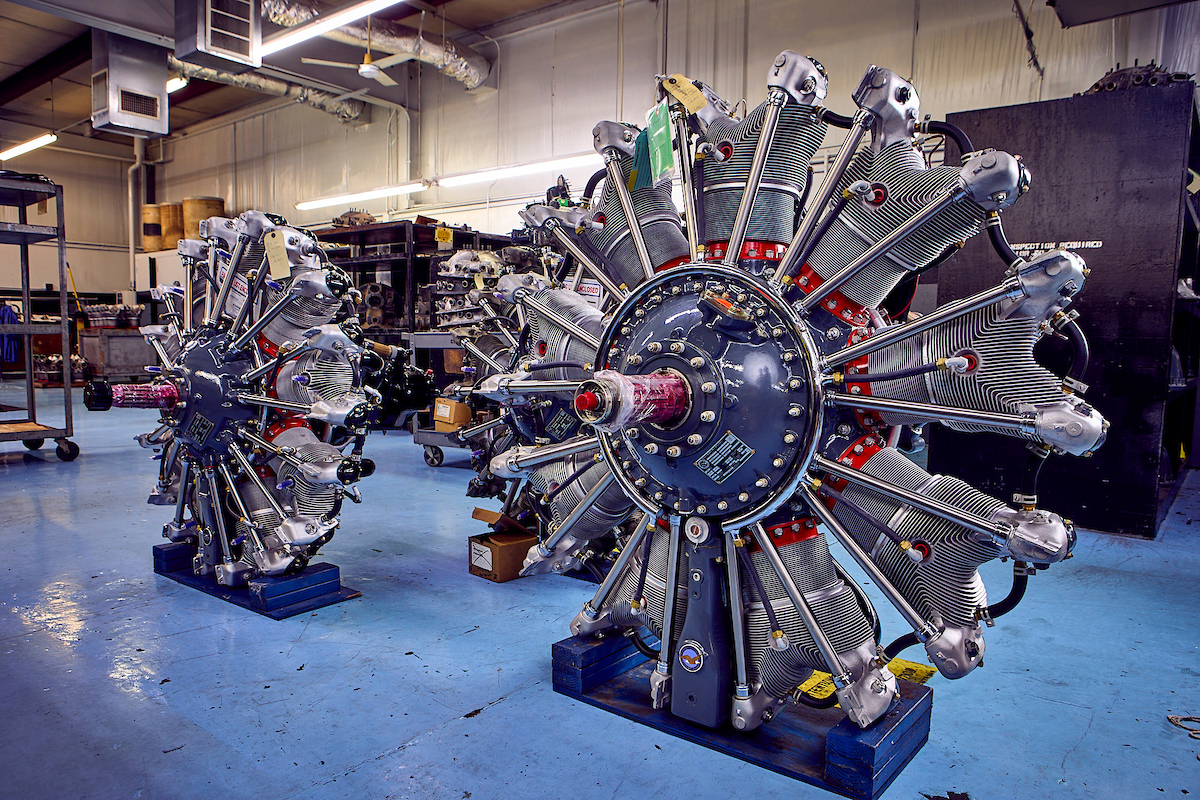

“How long did you say the engine sat idle?” What should be done to an engine to return it to service after it has sat idle for years? Answering that question requires answering several other questions: Was the engine preserved before it was stored? Was it stored in a climate-controlled facility? No? Out in the weather? Were the exhaust stack(s) and carburetor air inlets plugged? Was the engine periodically run up to operating temperature? Did it have preservative oil run in the engine before entering storage?

Please allow me to offer a few basic suggestions on short-term radial engine preservation storage:

- Change oil prior to storing an engine as old oil may be contaminated with acids & moisture that can cause corrosion or rust damage to expensive parts. Be sure to run the engine after the oil change to get the new oil circulated through the engine.

- Spray some oil into the cylinders, especially upper cylinders. Compression rings run pretty dry and can rust amazingly fast in storage.

- Plug up the exhaust outlet: Humid air/moisture can move past open valves! There are always some valves open at any given time and the moisture can cause corrosion or rust to intake valves and intake as well as exhaust ports.

- Engines being stored without full preservation should be turned through each week.

- Call us for information or supplies needed for preserving your engine!

Engine preservation for the radial engine, if done right, isn’t a subject that I can adequately address in a few quick lines! Concerning those instructions, refer to a copy of the manufacturer’s maintenance manual, part number 118611, Engine Preservation chapter.

By Ron Hollis