PT6…

Craymer’s Counsel

I have received questions and heard many discussions about oil recently, so this month, let’s dive into oil. When it comes to engine oil there are several choices and your experience has helped you determine the correct type of oil for your operation.

Just for knowledge, Pratt and Whiney Canada provides lists of approved oils in the first service bulletin of every engine series. For instance, service bulletin 1001 covers approved oils for all the small PT6’s covered by the 1000 series service bulletins. In this service bulletin, there is information about engine oil types and it lists the approved, by Pratt and Whitney Canada, to be used in PT6 engines. The oils are subdivided by viscosity and other factors. In my experience, most people use 2380 as their oil of choice. This oil is found on Table 3 of the service bulletin which includes other commonly used oils like Mobil Jet II and Aeroshell 500. Please make sure that the oil you choose it an approved oil.

The first of the discussion topics I have heard is about servicing. When servicing, the first point is don’t intermix oils. The service bulletin tells you not to intermix oils of different viscosities or specification as those oils may not be compatible with one another. If you find yourself in a situation where your oil was intermixed, there are instructions on how to drain and what level of engine flushing is required to ensure the engine is protected.

Secondly you want to check your oil at the right time. Always check your oil within 15 minutes after shutting down. This will help you get the most accurate gage of your oil level. Nothing is worse than oil pouring out from every spot on the engine from over service. It would be terrible to have to drain all the oil out of an engine to reset the oil level when it has been over serviced. A PT6 will always find the oil level that it wants to run at and will push out the extra.

Another hot topic is the engine “hiding” oil. This mostly occurs on large PT6 engines and can happen for a couple of different reasons. If, after sitting overnight or longer, or motoring your engine during washing there is no oil on the dipstick, what do you do? My advice has always been look around on the floor, if there is not a big puddle of oil then the oil is still in the engine. Start the engine, paying extra attention to the oil pressure and temperature. When the oil comes up to temp then you can shut the engine down and check the oil level. You don’t want to just start adding quarts of oil as that just becomes a mess.

How can an operator keep the engine oil healthy? First, make sure the chip detectors are working. We check chip detector function at every 100-hour inspection. The system is designed to alert the pilot at the earliest possible moment when something is going on that needs attention. Secondly, changing your oil. Pratt and Whitney Canada has said for a long-time engine oil doesn’t need to be changed. However, they caution operators to be aware of all the environmental issues that could affect or contaminate oil. In our industry, the air is not always as clean as we would like even though the airplanes run filtration. You also want to be aware that airframe manufacturer’s may require engine oil changes. Lastly, there are engine oil sampling programs available. Historically labs have been used to review oil samples, patch samples and oil filters to provide information. Pratt and Whitney Canada has also started an oil monitoring program. You can go to their website pwc.ca and get a kit. The advantage with using the P&WC kit is they can provide engine part specific data if they flag a problem. P&WC can tell you that gear or bearing metal is on the increase in your oil sample and advise actions on how to move forward with inspection or maintenance.

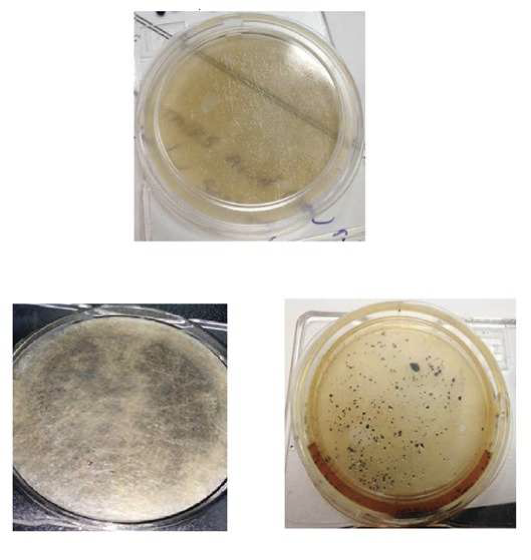

I want to wrap up this discussion with a word about “dark oil”. This phenomenon seems to occur from time to time in large PT6 engines. Pratt and Whitney Canada has come up with some solutions to issues related to this topic. There are several service bulletins introducing some temperature resistant packings to help limit the opportunity for carbon build up in oil. They also have provided some options for higher temp oils. Pratt and Whitney Canada has a list of approved oils in Table 4 of the approved oil service bulletin. These are listed as “High Thermal Stability” oils. Per instructions in the service bulletin these can be mixed with Table 3 oils. Make sure you follow the instruction. I had a customer tell me that the instructions for changing to one of these high temp oils have changed from time to time and there was confusion on how to use them. To my knowledge the instructions have never changed. If you want to move from BP2380 (Table 3 oil) to a high temp oil like Aeroshell 560 (Table 4 oil) to reduce or avoid dark oil. Examine your oil and filter, if carbon level is “acceptable” (see photos inserted here from service bulletin) then you can use the top up method.

This simply means when you need to add your next quart of oil that you use the high temp oil, Aeroshell 560 in our example. If you have excessive carbon in your oil you may need to drain the oil and flush per the instructions, then refill the oil tank with your original oil. We then can employ the top up method per the instructions. These high temp oils have a detergent quality to them and will start to move the carbon out of your engine and into the oil filter. The whole idea is that you don’t want to drop all the Table 3 oil out and service the engine completely with Table 4 oil because it could potentially clog all the oil strainers and nozzles in the engine. Following the proper guidelines allows for a controlled removal of carbon from the engine. I always recommend that you discuss this with your mechanic, engine maintainer and, of course, read the manuals. Use the resources around you to make the most informed decision.

Please reach out to me at robertc@covingtonaircraft.com if you have any questions and I’ll be glad to assist.